GageCal Software

The Standard of Accuracy

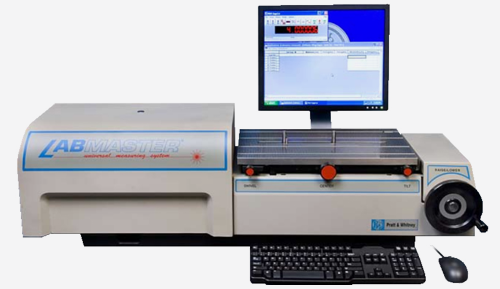

Powerful and resourceful, Pratt & Whitney's GageCal® control software sets a new standard for user-friendly calibration and part measuring. By controlling the operation and facilitating data collection, GageCal increases total measurement productivity. And with a graphics-rich user interface, you'll be amazed with how simple it is to use. GageCal is included with the following product lines: Labmaster Universal Model 175, 1000M, 1000A (with scripting), BM175, BM1000M, BM1000A, Labmicrometer Model 900, 1600, External Supermicrometer Model PC, Universal Supermicrometer Model 501, 504. GageCal is an optional add-on for the External Supermicrometer Model C and Digital Measuring Machines. We designed GageCal to be intuitive and self-teaching. So much so, that the extensive context sensitive HELP screens are seldom called upon. Mouse or hot key driven, with pull down menus and icons that let you "click" your way through calibration, GageCal helps put you at ease, so you can concentrate on the business of measuring. And the Microsoft® Windows environment allows multitasking and data export with other programs, such as gage management, EXCEL®, WORD®, or any other WINDOWS® program. Pratt & Whitney’s commitment to accuracy, reliability, and user satisfaction is reflected in GageCal. This commitment affirms its status as a trusted tool for calibration professionals worldwide.

Powerful and resourceful, Pratt & Whitney's GageCal® control software sets a new standard for user-friendly calibration and part measuring. By controlling the operation and facilitating data collection, GageCal increases total measurement productivity. And with a graphics-rich user interface, you'll be amazed with how simple it is to use. GageCal is included with the following product lines: Labmaster Universal Model 175, 1000M, 1000A (with scripting), BM175, BM1000M, BM1000A, Labmicrometer Model 900, 1600, External Supermicrometer Model PC, Universal Supermicrometer Model 501, 504. GageCal is an optional add-on for the External Supermicrometer Model C and Digital Measuring Machines. We designed GageCal to be intuitive and self-teaching. So much so, that the extensive context sensitive HELP screens are seldom called upon. Mouse or hot key driven, with pull down menus and icons that let you "click" your way through calibration, GageCal helps put you at ease, so you can concentrate on the business of measuring. And the Microsoft® Windows environment allows multitasking and data export with other programs, such as gage management, EXCEL®, WORD®, or any other WINDOWS® program. Pratt & Whitney’s commitment to accuracy, reliability, and user satisfaction is reflected in GageCal. This commitment affirms its status as a trusted tool for calibration professionals worldwide.

GageCal (6.0) Specifications (end-of-life)

- GageCal 6.x Installation CD [part# UPG-GCAL; sold per-instrument license].

- GageCal version 6.x is tested on 32-bit Windows XP, 32 and 64-bit Windows 7, and 64-bit Windows 8/8.1 and Windows 10.

- GageCal version 1.0-4.10 are obsolete.

- GageCal version 6.x is at end-of-life. No feature updates or patches are expected.

GageCal (7.0) Specifications/Features - latest version

Specifications:

- For the latest Software and User's Manual revision level, please contact the Pratt & Whitney Service Department or fill out our Contact Form. Proof of ownership and instrument serial number is required for downloads, installation CD, or hard copy User's Manual. Processing Fee applies to a lost CD or USB flash drive. User's Manuals are available in hard copy form only (part number/price is available on accessory price list). Company policy precludes sending electronic copy of User's Manuals.

- GageCal 7.x Installation CD [part# UPG-GCAL; sold per-instrument license].

- GageCal 7.x Installation USB Flash Drive [part# UPG-GCAL-USB; sold per-instrument license].

- GageCal version 7.x requires Windows 10 (32 or 64 bit) Version 21H2 or later, or Windows 11.

- GageCal version 7.x may run on Windows 7,8, or 8.1 (no longer tested or supported). GageCal 7.x will not run on Windows XP or Vista.

- Please contact the Pratt & Whitney Service Department for hardware, software, and firmware* requirements. *USB box firmware may require updating (firmware included on GageCal Installation CD/USB Flash Drive).

- The GageCal end user license agreement requires one purchased copy of GageCal per instrument. GageCal is included with most applicable instruments. Please supply the serial number of the associated instrument when requesting a GageCal upgrade.

New Features:

- Better Support for Large Monitors

- Temperature and Contact Correction: allows a user to set a datum, or do a two point calibration, using a master that is made of a different material, or is at a different temperature, than the artifact (part being measured).

- We have changed the way gauge calibration applications are selected. No more application buttons and drop menus. Simply open the “New Application” dialog by clicking on the spreadsheet icon, then select your application, standard, and grade, and start measuring.

- New guage calibration applications for the Labmaster: Bore Gages, Ball Bars, Micrometer Heads, Test Indicators, Tapered Plain Plug Gages, Thread Measuring Wires (Master and Working Sets) with support for ANSI/ASME B89.1.17-2001 tolerances.

- New custom applications allow the user to integrate LibreOffice® or Microsoft® Office spreadsheet applications into GageCal. Custom Applications are listed in the GageCal Application Suite spreadsheet selector. P&W has already loaded some custom applications to get the user started:

- Taper Ring

- Thread Micrometer Setting Standard

- Tapes and Rules

- NPT Thread (National Pipe Thread) Standards (Ring and Plug)

- Balls (Size Tolerance and Gauge Determination)

- Deep Groove Ball Bearings

- Roller Bearings

- Bearing Radial Internal Clearance

- Bearing Axial Internal Clearance

- BSPT Thread (British Standard Pipe Taper) Standards (Ring and Plug)

Coming soon:

- Taper Ring

- Temperature and Contact Correction with attached Environmental Weather Station:

-

This feature allows the use of masters made from any material and at any temperature to set a datum or perform two-point mastering. The digital readout displays the STP-calibrated size of an artifact, regardless of material, temperature, or time after mastering. It maintains a stable internal scale indefinitely, even in changing environmental conditions.

Smart Spreadsheets Speed Up Data Entry

Faster measurement begins with selection an icon (or pressing the hot key) to first mater the instrument, and then calibrate your particular gages. The user can choose between pre-defined applications (Gage Blocks, Rings, Plugs, etc.) and Free Measure (for custom applications). With an application selected, dialog boxes will continuously prompt the user for information that will build and open a "smart" spreadsheet. This "smart" spreadsheet, in the case of pre-defined applications, will automatically enter nominal sizes, tolerance bands, define best wire size for thread measurements, calculate pitch diameters and flag out of tolerance conditions as appropriate.

The operator simply choose the class of gage (i.e., XX or XXX), in the dialogue box, selects the appropriate cell in the "smart" spreadsheet, and clicks on the close probe icon (or presses the footswitch). GageCal displays the measurement in the "Current Reading" window and automatically updates the record. The data can be saves, printed in a customized report, or exported to many popular gage management software packages.

GageCal Scripting - Labmaster Universal Model 1000A

For even more automated control, GageCal scripting allows the user to create a sequence of automated actions for complete automatic measurement of custom parts or gages. For ultimate ease of use, scripts are written in Notepad (text editor in Microsoft® Windows). Automated positioning, alignment, and measurement practically eliminate operator influence and decrease measurement time. Instrument configurations, including table alignment and position, can be saved and recalled at a later time, minimizing setup time for common artifacts.

Below is an example of a ring gage script:

Z=1.375 'move to top position (1.375 inches from ring base)

ALIGN=TILT 'do automatic tilt alignment

ALIGN=CENTER 'do automatic center alignment

WAIT=5 'wait 5 seconds

WRITE=MEAS,GAGECAL 'write the measurement to GageCal

Z=0.75 'move to middle position

ALIGN=CENTER

WAIT=5

WRITE=MEAS,GAGECAL

Z=0.125

ALIGN=CENTER

WAIT=5

WRITE=MEAS,GAGECAL

MSG=Rotate ring then Press OK. 'ask user to rotate ring

Gage Management (optional)

Our optional gage management module, designed in accordance with ISO 17025 and ISO 9000, puts gage information at your finger tips. It represents a logical addition because it makes storing, retrieving and reporting gage information quite simple. You will be able to track and display gage history, wear data, current users, the product evaluated with the gage, calibration dates, days since last calibration, and much more.

Additional subsystems of the gage management module include gage studies, gage crib, gage preventive maintenance, and gage archives. With them you'll be able to control your gage data as well as your gages. The reporting system is extensive, offering both standard and custom reports. Common reports include standard calibration reports, gages due, recall letters, gage lists, supplier summaries, gage study listing and many more.

Free USB

Free USB Product &

Product & Celebrating

Celebrating