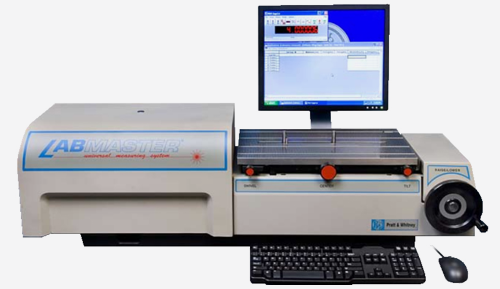

At Delta Airlines’ Calibration Laboratory, the Pratt & Whitney Labmaster Universal has again proven itself as a resource that will expand and enhance the capabilities of any laboratory that makes dimensional measurements. When the probes of the Labmaster close on a part, or open in an inside dimension, a user can detect variation down to 0.0000001 inches [0.0025 micron]. Meaningful data at this high resolution allows a user to position measured artifacts for micro-inch accuracy. With adherence to a few basic metrology principles and minimal training, a laboratory technician can use the Labmaster Universal to perform highly accurate calibrations with speed and efficiency, to gather reliable data for the dimensions of parts of various geometries, and to generally perform at a level unachieveable without the easy-to-use Labmaster Universal.

The Labmaster Universal has dramatically increased the speed of Delta’s Calibration Laboratory. “Until we owned the Labmaster, we did not have an efficient method to calibrate most of our gages,” expressed the Lead Metrologist at Delta’s lab. Now the laboratory calibrates more than 500 ring and plug gages, thread gages, pin sets, and gage block sets each year. The Labmaster Universal facilitates a quick turn around time and enables Delta’s lab to handle this quantity of gages. The quick turn around time leads to a second benefit for their lab; they no longer need to maintain duplicate gages. “We have the ability to measure and return to service most of these gages within a day or two, which eliminates the need to own duplicate gages. The longest part of the calibration process is the normalization time (which is typically overnight).”

The Labmaster Universal has increased the value of the laboratory and its Metrologist to the parent company. “Our Labmaster is the best quality investment we have made in the Delta dimensional calibration lab in the past ten years.” The lead Metrologist estimates the value of the annual calibration of 300 ring gages at approximately $9000, gage block sets at $2000 and several other calibrations at another $3000 - $5000. “The annual estimated value at Delta for calibrations performed on the Labmaster would be about $15,000 annually.”

The use of the Labmaster Universal has increased the reliability of the data produced by Delta’s Laboratory, and increased the laboratory’s confidence in its own measurements. Delta has learned that they can rely on the Labmaster Universal’s high accuracy not only for calibrating gages, but also for measuring aircraft components. “There are some aircraft parts designed and built to very close tolerances. Our Labmaster is occasionally used as the final word on parts being in tolerance. Vendors usually concur with our measurements”. Delta’s laboratory has rejected rings for being out of tolerance by only a few millionths of an inch; they have that degree of confidence in their Labmaster Universal.

The bottom line…At Delta the Labmaster Universal is used to make $15,000 worth of calibrations each year, Delta and Delta’s suppliers trust the LMU to millionths of an inch, and the laboratory Metrologist feels proud of and satisfied by the years of reliable data that he has collected; “If you ever need a good referral, send them my way. We could not be more pleased. I have loads of data to brag about.”

Free USB

Free USB Product &

Product & Celebrating

Celebrating