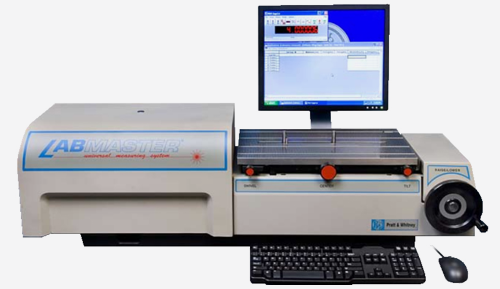

Universal (ID/OD) Presetting Instruments

The Standard of Accuracy

If gage setting and calibration is important to you, choose the Labmicrometer Model 900 or 1600 measuring system. Designed for gage calibration laboratories and shop floor environments requiring precise internal and external measurements over long lengths. Additionally, the Labmicrometer is ideal for use as a setting bench and adjusting instrument offering precision setting of inside and outside comparative measuring gages, micrometers, snap gauges, as well as other measuring tools. Common applications include measurements of end/length standards, long gage blocks, plug/pin gages, thread gages, and rings/discs.

Setting Bench Measuring Applications:

- End Standards / Bar Gauges / Ball Bars

- Cylindrical Setting Gages

- Gage Masters

- ID/OD Large Diameter Rail Gages

- Setting Standards (Frames, Rods)

- Snap Gages

- Large Diameter Gages (special frames: bridge, hump, "C", donut, adjustable)

- Dial Bore Gages / Swing Gages / Shallow Diameter Gages

- ID/OD Adjustable Frames

- Master Setting Bars / Setting Masters / CMM Masters / Precision Parts

Features & Benefits of the Labmicrometer®:

- Two instruments in one - calibration and setting bench instrument (hand held tools and preset indicator style gages)

- Digital laser interferometer with zero Abbe offset - for maximum resolution, traceability, and performance

- Wide direct-reading range - No remastering required over gage’s entire measurement range

- Mechanical and thermal stability - Rugged, time-tested, cast iron base ensures reproducible results even in shop floor environments

- Variable force (standard) - Built-in, PC displayed force system offers measurement-independent adjustable force

- Integrated probe lock (standard) - provides adjustable rigid positioning used for setting hand held adjustable gages

- Two-point calibration - Allows for continuous, accurate measurements over the gage’s entire measurement range

- GageCal® Software - Microsoft Windows® based software reduces data entry, eliminates transcription errors, and speeds up measurements

- Single-axis measuring table (standard) - Large surface area and T-slots provide for quick and simple fixturing and part alignment

- Multi-axis measuring table (optional) - Offers five axes of motion for added control of part alignment

- Bi-directional probes (optional) - Eliminates time-consuming setup changes

Specifications:

| Model / Part # | LM-900 (U306685) | LM-1600 (U306922) | ||

| Table Axes of Motion | Elevation, 2-axis Centering, Tilt, and Swivel | |||

| Accuracy | 5+ 0.7L µinch | 0.125 + 0.7L µm | 5 + 0.7L µinch | 0.125 + 0.7L µm |

| Repeatability | 3 µinch | 0.08 µm | 3 µinch | 0.08 µm |

| Measurement Range: Internal | 0.04-34 inches | 1-860 mm | 0.04-62 inches | 1-1575 mm |

| Measurement Range: External | 0-36 inches | 0-910 mm | 0-64 inches | 0-1625 mm |

| Direct Reading Range | 36 inches | 910 mm | 64 inches | 1625 mm |

| Measuring Force | -8 to 40 oz. | -225 to 1100 g | -8 to 40 oz. | -225 to 1100 g |

*Model LM-3050 also available: 0-120 inch (3048 mm) measurement range

Free USB

Free USB Product &

Product & Celebrating

Celebrating