The lead tribology Metrologist of one NASA laboratory stated “The radial internal clearance and axial internal clearance kits for the Labmaster Universal will help further establish us as a very capable bearing research lab”.

This friction and wear research lab uses a Pratt & Whitney Labmaster to measure several critical precision bearings from 12 mm bore, 2000 rpm bearings used in the water recycling system of the International Space Station to 90 mm bore, 30,000 rpm turbopump bearings used on the Space Shuttle’s rocket engines. “We are getting more use out of the Labmaster than I actually anticipated… It is a great tool to correlate some of the precision roundness and form metrology work we perform. My interns are still amazed at how they can routinely dial it in to 2 millionths [0.05 microns] on our reference gage blocks.”

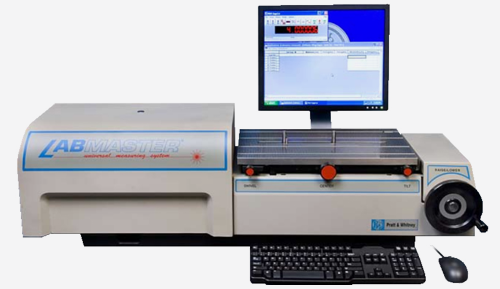

The Labmaster was designed with the operator in mind; simple controls allow an operator to eliminate cosine error by fine-tuning the position of measured artifacts. In most cases, even cosine or misalignment errors less than 1 micro-inch [0.025 microns] can be detected and eliminated. Pleased with the results of his bearing measurement projects, the lead Metrologist of the research laboratory intends to explore the full potential of the Labmaster, “I look forward to expanding the capabilities of this great tool even more!”

Originally designed for measuring ID/OD gages such as threads, plugs, rings, and blocks, the Labmaster is also fit for applications such as measuring optical components, gears, splines, film thickness, and API gages. Pratt & Whitney Measurement Systems offers on-site training and an assortment of Labmaster accessories to aid in these and other special measurement applications

Free USB

Free USB Product &

Product & Celebrating

Celebrating