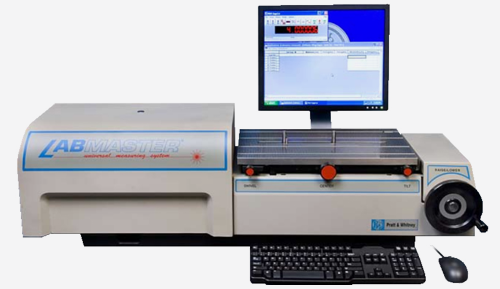

At many US aerospace corporations, the Labmaster Universal Model 175 has proven its value as an essential tool for measuring aircraft gages and components. When the Labmaster Universal Model 175 scale is set by two point calibration, the user can determine if parts are within tolerance in minutes. Thanks to the Labmaster Universal Model 175's adjustable table position and orientation, the user can to verify screw thread pitch with micro-inch accuracy. With adherence to a few basic Metrology principles and minimal training, a typical laboratory technician can use the Labmaster Universal Model 175 to verify screw threads.

The Labmaster Universal Model 175 has significantly improved the inspection of first piece parts, random sampling of production parts, and settling any dispute regarding parts' meeting tolerance of many US aerospace corporations. One facility estimates that they handle dozens of measurements that are critical for manufacture of millions of dollars of parts including ball bearings, ball bearing race (inner race and outer race), gears and splines, and threads each year. The adjustable reference table allows the calibration technicians to quickly measure thread pitch and form.

The Labmaster Universal Model 175 has shortened measurement turnaround time. One aerospace facility estimates the value of the annual calibration of two dozen master splines at approximately $4,800, 50 reference threads at $5,000, and 36 plain ring gages at $5,000. The annual value of measurement using the Labmaster Universal Model 175 for that facility is approximately $14,800.

Use of the Labmaster Universal Model 175 has boosted confidence in measurements, and has allowed finer and finer differentiation. Many US aerospace corporations have learned that they can rely on the Labmaster Universal Model 175's limitless adaptability not only for finding out of tolerance dimensions, but also for calibrating masters for reference dissemination throughout even the largest facilities. Many US aerospace corporations use the LMU 175 to distinguish good from bad at tolerances of a few millionths. The list of calibration capabilities is always growing.

Press Contact:

Pratt and Whitney Measurement Systems, Inc.

Director, Marketing & Communication

Phone: (800) 371-7174

Email: info@prattandwhitney.com

Web site: www.prattandwhitney.com

Pratt & Whitney Measurement Systems and the P&W logo are registered trademarks of Pratt & Whitney Measurement Systems. All other trademarks are the property of their respective owners.

Free USB

Free USB Product &

Product & Celebrating

Celebrating