Although thread lead checks are sometimes ignored in today’s cost-sensitive Metrology laboratories there are two important reasons to insure correct thread lead:

- For correct thread mating, i.e., prevent binding and

- For accurate thread lead advance when the thread is used in a measurement application, e.g., a hand micrometer.

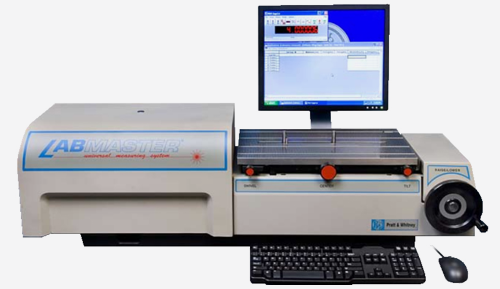

For many years Metrologists have relied upon the venerable Pratt & Whitney Electro-Mechanical Lead Tester. Today, designed in accordance with the popular Pratt & Whitney Lead Checker, the Pratt & Whitney Labmaster Universal can measure several attributes of thread gages including the thread lead with the Lead Fixture Assembly (part# U306784). This accessory adds an additional thread capability to the Labmaster line, which already includes internal parallel thread pitch/minor diameter, external parallel thread pitch/major diameter and external National Pipe Tapered (NPT) pitch diameter.

High accuracy is maintained by its laser interferometer, zero Abbe offset design, and large measuring table with center position, height, pitch, and yaw controls. The computer-controlled precision air bearing slide and gaging fingers remove operator-influenced errors commonly observed with traditional gaging methods by maintaining constant force. It also greatly minimizes wear and tear to both the measuring standards and the instrument.

The ULM is also capable of measuring gage blocks, end standards, plain rings, threaded rings & plugs, API gages, pin & plug gages, tapered plugs, cylindrical setting gauges, micrometers, indicators, LVDTs, calipers, and snap gauges with instrument uncertainty to 2 millionths of an inch (0.05 micron). It is suitable for virtually all ID and OD gage calibration applications through its wide 0.020-inch (0.5 mm) to 14-inches (356 mm) measuring range. The ULM includes Pratt & Whitney’s GageCal software that automatically enters tolerances for rings, plugs, pins, balls, threads (calculates pitch/major diameter) and flags out of tolerance conditions.

Free USB

Free USB Product &

Product & Celebrating

Celebrating