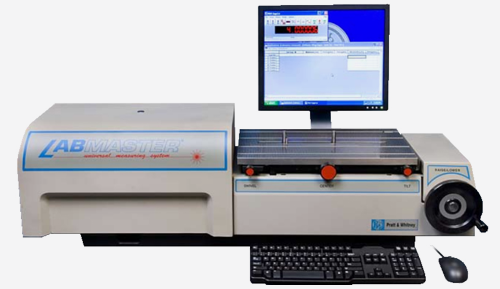

Adapting Custom Applications to the Labmaster Universal

The Labmaster Universal is designed mainly for one dimensional gage calibration (gage blocks, master rings, plug gages …), but can be used for many other artifacts and part measuring. Two things that need to be considered when measuring custom artifacts is probe contact and how to attach the artifact to the measuring table.

Probe Contact

A wide variety of probes have already been designed for the Labmaster Universal, so we may already have probes that meet your needs. We also design custom probes if needed. Point contact between the probe and artifact usually results in the best (lowest) repeatability, line contact results in higher repeatability, while surface contact results in the highest (worst) repeatability. Use point contact whenever possible. Spherical probes provide point contact for measurement of standard shapes such as blocks, cylinders, bores, grooves, and spheres. Flat probes provide point contact for objects with spherical surfaces such as balls, ball bars, and end standards with spherical faces. Flat probes are also good for measuring small, thin, or flexible artifacts such as small balls, thin wires, or flexible film. In some cases, additional gages are required in order to complete a measurement. Some examples of this are thread wires, gear wires, and the use of gage blocks and pins for the measurement of taper plug gages. Probes can be designed to handle almost any type of geometry. For example, thread micrometer set standard measurement probes have been designed that contact a conical point on one end of the artifact and a v-notch on the other end of the artifact. The thread mic probes provide point contact while minimizing potentially large sine errors found in other methods of measurement. Contact Pratt & Whitney if you have questions on how the Labmaster Universal could contact your artifact.

Artifact Fixturing

The object of artifact fixturing is to attach the artifact to the measurement table without distortion and to place the desired measurement dimension in line with the measurement axis. It is also desirable to be able to quickly and easily load and unload the artifact from the fixture. Locating posts on the measurement table are used to align gage blocks and to center cylindrical plugs and rings. T-slots in the table accommodate accessories that aid in positioning and holding an artifact. Since the standard gaging for the Labmaster Universal is 0.5 ounces, many parts do not need to be clamped to the measurement table. The measurement table has 4 axes of adjustment (height, center, tilt, and swivel), so many times fixturing just needs to place the artifact in approximate position and table adjustments will take care of any fine positioning. Both of the measurement probes float, which eliminates the need for accurate zero positioning. The Labmaster Universal has fixturing to handle most of the standard shapes such as blocks, cylinders, rings, and spheres. The Labmaster Universal also has fixturing to handle standard gages such as micrometers, calipers, bore gages, and threaded plugs. Contact Pratt & Whitney if you have questions on how we could fixture your part on the Labmaster Universal.

Free USB

Free USB Product &

Product & Celebrating

Celebrating