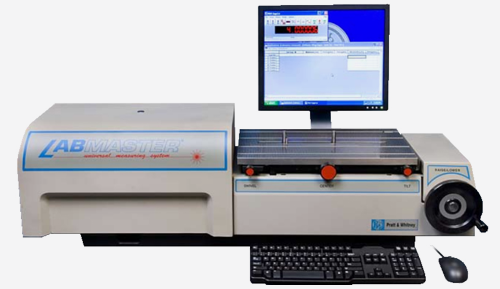

Labmaster Bearing Measuring Instrument - Model BM175, BM1000A, BM1000M

The Standard of Accuracy

The Labmaster Bearing Measuring Instrument (Model BM175, BM1000A, BM1000M) can measure a wide range of anti-friction bearings including tapered roller bearings, needle roller bearings, ball bearings, spherical roller bearings, and cylindrical roller bearings. Easy to use and the most accurate bearing measuring instrument on the market today, the BM Series Labma ster Universal measures bearings used for the aerospace, automotive, and medical industry. For the bearing re-manufacture and repair industry, the BM Series includes probes and fixtures for measuring axial internal clearance (axial play) and radial internal clearance (radial play). These accessories can also measure bearing wear and provide important failure analysis.

ster Universal measures bearings used for the aerospace, automotive, and medical industry. For the bearing re-manufacture and repair industry, the BM Series includes probes and fixtures for measuring axial internal clearance (axial play) and radial internal clearance (radial play). These accessories can also measure bearing wear and provide important failure analysis.

Bearing Characteristics that can be measured:

- Radial Internal Clearance (Radial Internal Play)

- Axial Internal Clearance (Axial Internal Play / End Play)

- Internal Diameter of Bearing (Inner Ring)

- External Diameter of Bearing (Outer Ring)

- Inner Raceway of Bearing

- Outer Raceway of Bearing

- Shield Thickness

- Ball / Needle Bearing Diameter

Features & Benefits of the Radial Internal Clearance (Axial Play) Kit:

- Differential Measurement - Eliminates errors due to deflections of machine elements and errors due to variations in mechanical connections.

- Floating Ring Design - Flexure support allows 6 degrees of frictionless movement with zero looseness. The force application system is also frictionless. The absence of friction and looseness ensures repeatability. The floating ring design allows precise alignment of the bearing races, which reduces misalignment errors.

- Horizontal Orientation - Minimizes errors due to the bearing deforming under its own weight. Eliminates the need for the force system to compensate for bearing weight.

- Concentrated Force Application - Minimizes error due to ring deflection. Radial Play Kit includes force systems (load presets) to satisfy ABMA, ANSI, ISO, as well as other standards.

- Performance Highlights - Highest accuracy, repeatability, and resolution on the market.

Gage Comparison:

|

"Other" Gage |

P&W Radial Internal Clearance Kit |

| Inner ring mounted on 3 Jaw chuck. If chuck is too tight then ring will deform. If chuck is too loose then gap will affect measurement. | No radial loads are applied when mounting the bearing. |

| Single ended measurement will include errors due to machine element deflections, fixturing looseness, and air bearing variation. | Differential measurement is unaffected by machine element deflections, fixturing looseness, or air bearing variation. |

| Large offset distance between the force application and reaction points causes bending of the bearing rings, which will add or subtract from the measurement. | Minimal offset distance (< 0.125 inch [3.175 mm]) between the force application and reaction points ensures minimal flexing of the bearing. A 0.125 inch offset will have 500X less deflection than a 1 inch [25.4 mm] offset. |

| No provision for precisely aligning the bearing races. Alignment will be affected by machine level and force application friction. | The floating ring design allows precise alignment of the bearing races, minimizing errors due to misalignment. |

| Friction in the force system due to cylinder seals causes force variation. | Frictionless force application minimizes force variation. |

| Friction between the force application V and the outer ring affects outer ring centering. | Frictionless force application allows the outer ring to auto-center. |

| Vertical mounting of the bearing allows the ring to deform under its own weight, directly affecting the measurement. | Horizontal mounting of the bearing minimizes ring deflection due to its own weight. Ring deflection is in a direction that does not directly affect the measurement. |

| Vertical mounting of the bearing means that the weight of the outer ring will add to the downward applied force and subtract from the upward applied force. | Horizontal mounting of the bearing ensures that the bearing load is unaffected by the outer ring weight. |

Axial Internal Clearance Kit (for ball bearings only) [part# U307334*]

Radial Internal Clearance Kit (for ball bearings only) [part# U307326*]

*Proprietary design. Please call for range/load specifications. Kits can be customized to meet specific bearing requirements. For measuring roller bearing radial and axial end play, measure the dimensions of the individual components and calculate the end play. Demonstrations are available at Pratt & Whitney Corporate Headquarters.

For more information, please contact the Pratt & Whitney Sales Department or fill out our Contact Form.

Free USB

Free USB Product &

Product & Celebrating

Celebrating