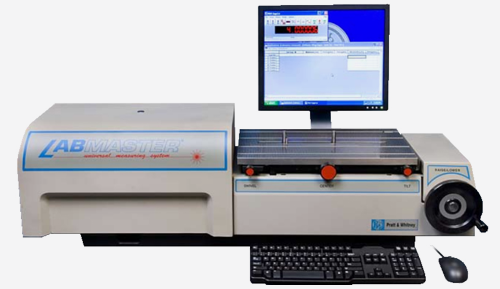

Labmaster Universal - Model 1000M

The Standard of Accuracy ...and the most popular instrument in industry!

With a 40 inch (1016mm) direct reading range and an 80 inch (2032mm) capacity with optional probes, this laser-based Universal Measuring System is designed for high accuracy, ID/OD/SD* gage calibration and part measuring. Swivel, centering, tilt, and elevation knobs are all standard and easy to use. Features include laser interferometer, computer control, air bearings, bi-directional probes, constant

measuring force, and flexible fixturing. These features offer guaranteed repeatability and operator independent reproducibility with unmatched speed.

measuring force, and flexible fixturing. These features offer guaranteed repeatability and operator independent reproducibility with unmatched speed.

With appropriate accessories, the LABMASTER Universal 1000M is capable of measuring rings (threaded & non-threaded), gage blocks, plugs (threaded & non-threaded), dial/test indicators, gage wires, micrometer heads, pin gages, tapered plugs (threaded & non-threaded), end standards, micrometers, and snap gages, all with NIST traceability. Only a handful of traceable masters, such as blocks, rings, etc. are needed (not included). The LABMASTER Universal 1000M can also measure a wide range of specialty applications such as ID/OD bearings (radial/axial clearance), balls, shafts, optics, as well as your precision parts. The LABMASTER Universal 1000M includes a current model computer loaded with GageCal, Pratt & Whitney’s Windows based measurement and control software. GageCal has predefined application screens and automatically enters tolerances for various types of measurements such as blocks, rings, plugs, and threads. P&W is accredited in accordance with the recognized International Standard ISO/IEC 17025:2005 by A2LA.

The Labmaster® Universal Model 1000M measures:

- Gage Blocks / Slip Gauges

- End Standards / Bar Gauges / Ball Bars

- Threaded Rings & Plugs

- Tapered Rings & Plugs

- Pin & Plug Gages

- Pipe Threads (API)

- Cylindrical Setting Gages

- Gage Masters

- Ball Bearings

- ID/OD Large Diameter Rail Gages

- Precision Measuring Tapes & Rules

- Roller Bearings (Tapered, Cylindrical, Spherical, Needle)

- Shafts

- Micrometers

- Setting Standards (Frames, Rods)

- Dial / Test / Digital Indicators

- Long Gauge Blocks and Meter Bars

- LVDTs

- Calipers

- Snap Gages

- Depth Micrometers

- Inside / Outside Micrometers

- Large Diameter Gages (special frames: bridge, hump, "C", donut, adjustable)

- Gears/Splines

- Lead Gage Setting Standards

- Ring Gages

- Dial Bore Gages / Swing Gages / Shallow Diameter Gages

- Master Setting Bars / Setting Masters / CMM Masters / Precision Parts

- ID/OD Threads - Detailed List

New Capability: ID/OD/SD*

- SD = Same-side Dimension (SD = both probes travel in same direction; For example: measurement of step gages)

Popular Measuring Options:

- API Threaded Connection Frames (NUE, LTC, EUE, Line Pipe, STC, Buttress)

- Dial Bore Gage Kit

- Radial Internal Clearance (RIC) kit / Radial Play Gage

- Axial Internal Clearance (AIC) kit / Axial Play Gage

- Internal and External Thread Gages

- Rotary Shouldered Connection Thread Inspection (semi-custom application)

- Gear / Spline Accesories

Specifications:

| Model / Part # | LMU-1000M (U308100) | |

| Table Axes of Motion | Elevation, Center, Tilt and Swivel | |

| Accuracy | 2 + 0.5L µinch | 0.05 + 0.5L µm |

| Repeatability | 1.6 µinch | 0.04 µm |

| Measurement Range: Internal* | 0.02 to 49 inches | 0.5 to 1245 mm |

| Measurement Range: External* | 0 to 48 inches | 0 to 1220 mm |

| Direct reading Range | 40 inches | 1016 mm |

| Measuring Force (standard) | 0.5 oz | 14 g |

| Measuring Force (optional) | 2 - 40 oz | 50 - 1100 g |

* Measurement Range to 80 inches (2032 mm) with optional probes and limited table movement.

* Measurement Range to 120 inches (3048 mm) with optional probes and limited table movement (part# U308658).

Free USB

Free USB Product &

Product & Celebrating

Celebrating